Deep well pump

Thispumpappliesdoublepumpbarrelstructure,ontheup-stroke,theliquidcolumnstaticpressurewithinthestringactsonpumpbarrelouter-wall,undertheactionofthepressure,theclearancebetweenthepumpbarrelandplungerisreduced,thuscandecreasethelowpumpefficiencycausedbyleakage;Ondown-stroke,duetothebalanceofinternalandexternalpressure,itcaneliminatethephenomenonofbilgepump,thussignificantlyextendthefatiguelifeofpumpbarrel.Uniquedesignofplungeranti-stuckcaneffectivelysolvethemechanicalimpurityandslightpumpstuckproblemsinsandproducingwells.Thispumpismainlyusedforthinoilwellwhichtheconventionalliftingtechnologycannotproduceduetotheinsufficientformationfluidandlowpressurecauses,thewelldepthiscommonlybetween2600~3500m. Pumpbore(mm) RangeofStroke(m) Pumpconstant Sizeofconnectingsuckerrodφ28 0.90 φ323.0~6.01.16CYG19φ38 1.63 φ44 2.19

category:

Oil pump class

WhatsApp:

E_mail:

Deep well pump

Details

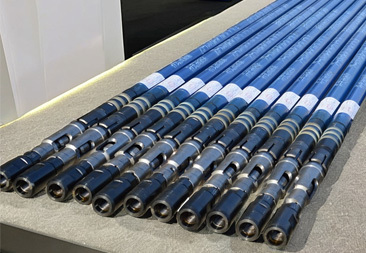

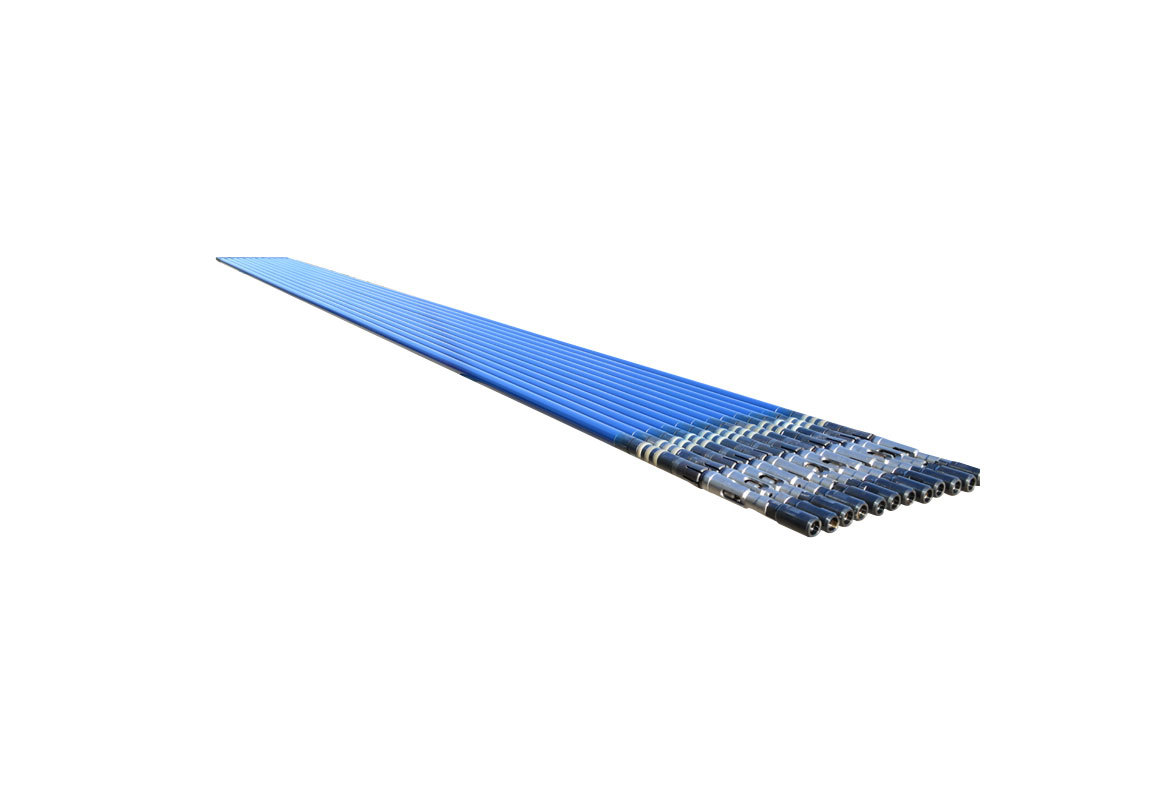

This pump applies double pump barrel structure, on the up-stroke, the liquid column static pressure within the string acts on pump barrel outer-wall, under the action of the pressure, the clearance between the pump barrel and plunger is reduced, thus can decrease the low pump efficiency caused by leakage; On down-stroke, due to the balance of internal and external pressure, it can eliminate the phenomenon of bilge pump, thus significantly extend the fatigue life of pump barrel. Unique design of plunger anti-stuck can effectively solve the mechanical impurity and slight pump stuck problems in sand producing wells.

This pump is mainly used for thin oil well which the conventional lifting technology cannot produce due to the insufficient formation fluid and low pressure causes, the well depth is commonly between 2600 ~ 3500 m.

|

Pump bore (mm) |

Range of Stroke (m) |

Pump constant |

Size of connecting sucker rod |

|

φ28 |

|

0.90 |

|

|

φ32 |

3.0~6.0 |

1.16 |

CYG19 |

|

φ38 |

|

1.63 |

|

|

φ44 |

|

2.19 |

|

previous page

next page

previous page

next page