Tubular pump

Tubingpumpischaracterizedbyitssimplestructure,andreliableproperties.Ithaslargerload-capacitybecauseofitsheavierwellofthebarrel.Insidewellofthebarreliscarbonizedorcarbonitrided,surfaceoftheplungeristreatedwithhardnesschrome.Thepumpissuitableforoilwellwithseverewearandslightcorrosion.Thewearresistingandcorrosion-proofpumpisdevelopedonthebaseofconventionalpump.Surfaceoftheplungerissprayedwithnickelbasealloy,insidewellofthebarrelisplatedwithhardnesschrome,thekeypartssuchasvalvecase,ballandseataremadeofstrongcorrosion-resistingandexcellentmechanicalpropertiesmaterial.Foroutstandingpropertiesofcorrosion-resistingandwear-resisting,servicelifeofthepumpis1-3timeslongerthantheconventionalpump. Pumpbore(mm) Lengthofplunger(m) Lengthofbarrel(m) Rangeofstroke(m) Pumpconstant Sizeofconnectingsuckerrod Sizeofconnecting(in)32 1.140CYG1923/8TBG38 1.642CYG1927/8TBG44 2.235CYG1927/8TBG570.6~1.22.1~7.51.2~6.03.694CYG1927/8TBG70 5.518CYG223TBG83 7.707CYG2231/2TBG95 10.261CYG254TBG

category:

Oil pump class

WhatsApp:

E_mail:

Tubular pump

Details

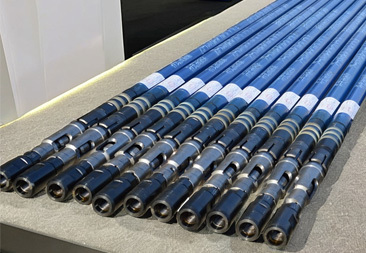

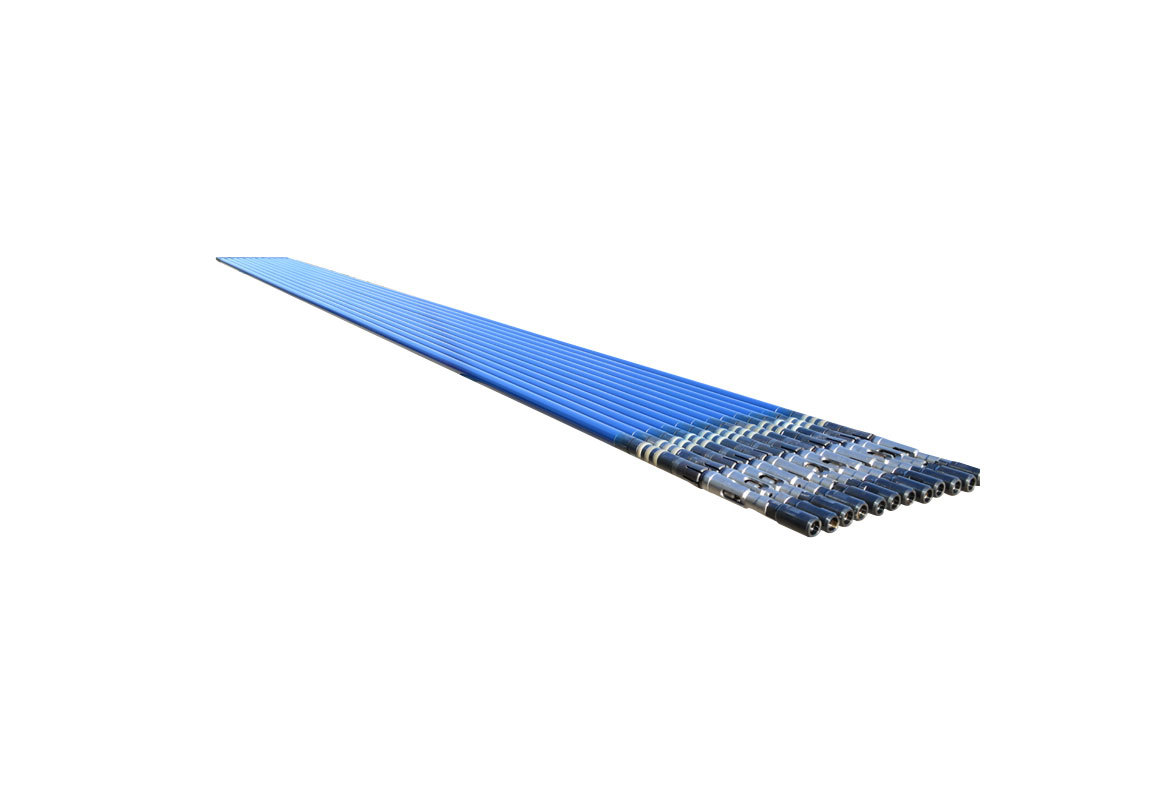

Tubing pump is characterized by its simple structure,and reliable properties.It has larger load-capacity because of its heavier well of the barrel.Inside well of the barrel is carbonized or carbonitrided,surface of the plunger is treated with hardness chrome.The pump is suitable for oil well with severe wear and slight corrosion.

The wear resisting and corrosion-proof pump is developed on the base of conventional pump.Surface of the plunger is sprayed with nickel base alloy,inside well of the barrel is plated with hardness chrome,the key parts such as valve case,ball and seat are made of strong corrosion-resisting and excellent mechanical properties material.For outstanding properties of corrosion-resisting and wear-resisting,service life of the pump is 1-3 times longer than the conventional pump.

|

Pump bore (mm) |

Length of plunger (m) |

Length of barrel (m) |

Range of stroke (m) |

Pump constant |

Size of connecting sucker rod |

Size of connecting (in) |

|

32 |

|

|

|

1.140 |

CYG19 |

2 3/8 TBG |

|

38 |

|

|

|

1.642 |

CYG19 |

2 7/8 TBG |

|

44 |

|

|

|

2.235 |

CYG19 |

2 7/8 TBG |

|

57 |

0.6~1.2 |

2.1~7.5 |

1.2~6.0 |

3.694 |

CYG19 |

2 7/8 TBG |

|

70 |

|

|

|

5.518 |

CYG22 |

3 TBG |

|

83 |

|

|

|

7.707 |

CYG22 |

3 1/2TBG |

|

95 |

|

|

|

10.261 |

CYG25 |

4 TBG |

previous page

next page