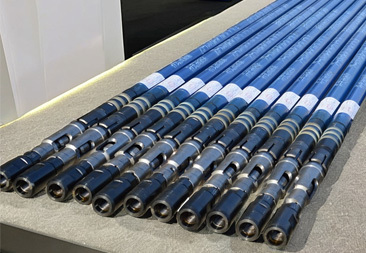

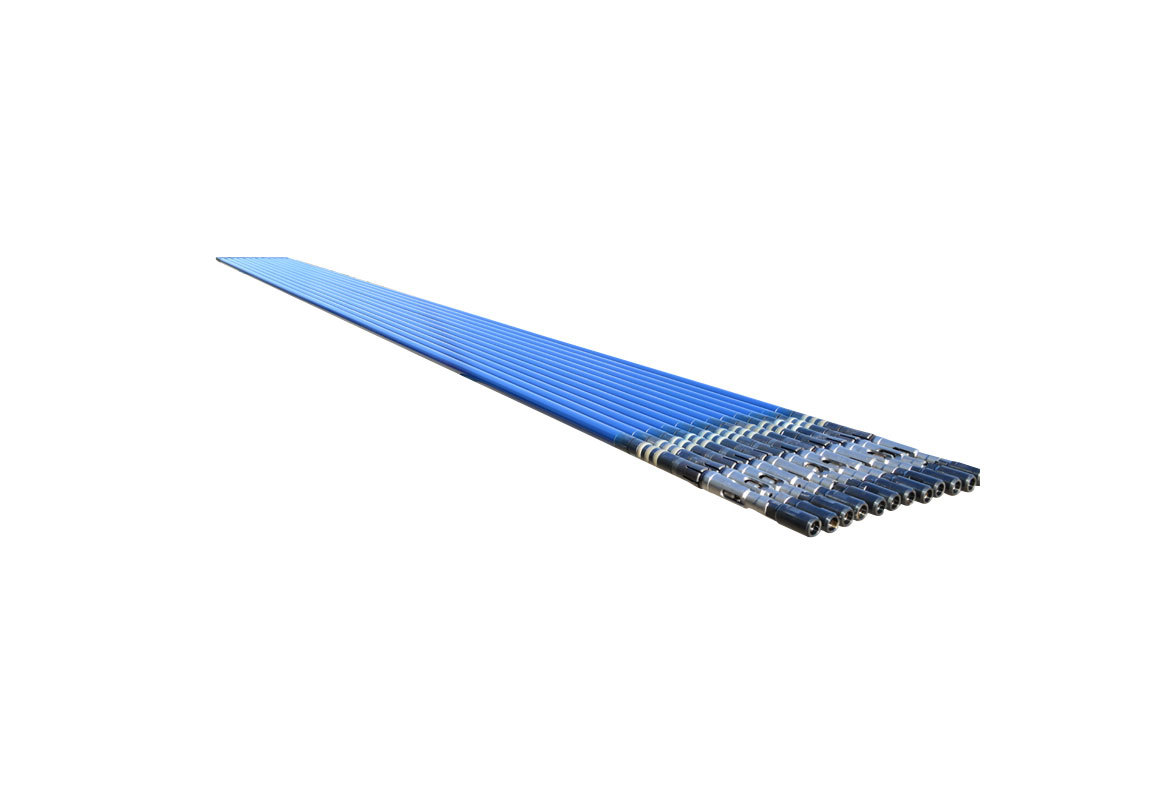

Elastic sealed horizontal well pump

Thepumpappliesthemultistagesealingstructure,independenteachotheratalllevels,andstrongonstrongoff,hastheanti-gasfunction;Cancelthetravelingvalve,singlestagesealunitadoptsnon-contactelasticclearanceseal,thisstructurecannotonlydecreasethesealclearance,reduceloss,improvethepumpefficiency,andchangetherigidclearancebetweenordinarypumpplungerandpumpbarrelintoelasticclearance,toavoidthepumpstuck,andcanavoidsanddamageonthesurfaceofthepumpbarrelandplunger,prolongthepumpinspectioncycle;Thestandingcageisequippedwithguidebaffle, andundertheactionofthepushrodandthespring,thevalveballisforcedtoshutdown. Thepumpissuitableforvarioustypesofwellssuchassandproductionwells,highdeviatedwells,horizontalwells,highgaswells,heavyoilandsteamstimulationwells,steamdrivewells,deepwellsetc. Pumpbore(mm) Lengthofplunger(m) Lengthofbarrel(m) RangeofStroke(m) Pumpconstant SizeofconnectingTubing(in) Sizeofconnectingsuckerrod Maxoutsidediameter(mm)φ32 1.14023/8TBGor 27/8TBGCYG19φ73/φ89φ38 1.64223/8TBG or 27/8TBGCYG19 φ44 2.23527/8TBG or31/2TBGCYG19φ89/φ108φ571.54.5~8.73.0~8.03.69427/8TBG or 31/2TBGCYG19 φ70 5.51831/2TBG or4TBGCYG22φ108/φ121φ83 7.70731/2TBG or 4TBGCYG25 φ95 10.2614TBG or41/2TBGCYG25φ121/φ132

category:

Oil pump class

WhatsApp:

E_mail:

Elastic sealed horizontal well pump

Details

The pump applies the multistage sealing structure, independent each other at all levels, and strong on strong off, has the anti-gas function; Cancel the traveling valve, single stage seal unit adopts non-contact elastic clearance seal, this structure can not only decrease the seal clearance, reduce loss, improve the pump efficiency, and change the rigid clearance between ordinary pump plunger and pump barrel into elastic clearance, to avoid the pump stuck, and can avoid sand damage on the surface of the pump barrel and plunger, prolong the pump inspection cycle; The standing cage is equipped with guide baffle, and under the action of the push rod and the spring, the valve ball is forced to shut down.

The pump is suitable for various types of wells such as sand production wells, high deviated wells, horizontal wells, high gas wells, heavy oil and steam stimulation wells, steam drive wells, deep wells etc.

|

Pump bore (mm) |

Length of plunger (m) |

Length of barrel (m) |

Range of Stroke (m) |

Pump constant |

Size of connecting Tubing (in) |

Size of connecting sucker rod |

Max outside diameter (mm) |

|

φ32 |

|

|

|

1.140 |

2 3/8TBG or 2 7/8TBG |

CYG19 |

φ73/φ89 |

|

φ38 |

|

|

|

1.642 |

2 3/8TBG or 2 7/8TBG |

CYG19 |

|

|

φ44 |

|

|

|

2.235 |

2 7/8TBG or 3 1/2TBG |

CYG19 |

φ89/φ108 |

|

φ57 |

1.5 |

4.5~8.7 |

3.0~8.0 |

3.694 |

2 7/8TBG or 3 1/2TBG |

CYG19 |

|

|

φ70 |

|

|

|

5.518 |

3 1/2TBG or 4TBG |

CYG22 |

φ108/φ121 |

|

φ83 |

|

|

|

7.707 |

3 1/2TBG or 4TBG |

CYG25 |

|

|

φ95 |

|

|

|

10.261 |

4TBG or 4 1/2TBG |

CYG25 |

φ121/φ132 |

previous page

next page

previous page

next page