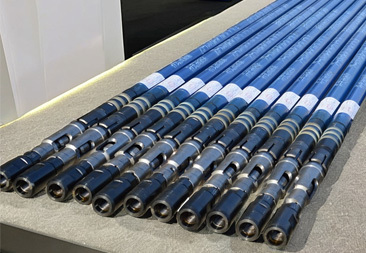

Sliding sleeve sucker rod centralizer

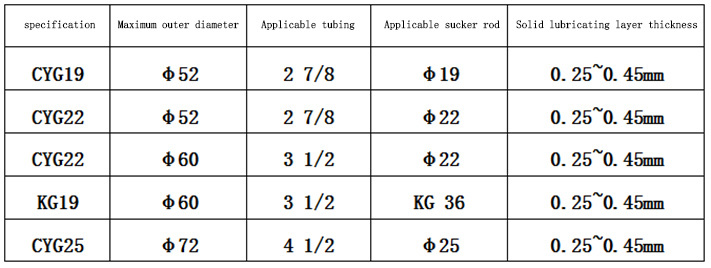

Uses:Theundergroundpetroleummachineryoftherightingsuckerrodreducesthefrictionbetweentherodandthetubeandenhancestheoilrecoverylifeofthepumpingunit.Structure:Theslidingsleevesuckerrodcentralizerconsistsofacorerod,aslidingsleeveandajoint.Features:1.Sprayathickmetallubricationfilmonthesurfaceofthecentralizerbyspraywelding.2.Thematerialofthemetallubricatingfilmisnickel-basedalloypowderwithanickelcontentof60%andothercomponentssuchaschromium,boron,silicon,andthelike.3.Withthreewear-reducingsurfaces,thelinecontactofthetraditionalcentralizerischangedtofacecontact.Thecontactismorecompleteandtheanti-biaseffectismoreobvious.

category:

Hardlined cage

WhatsApp:

E_mail:

Sliding sleeve sucker rod centralizer

Details

Uses:

The underground petroleum machinery of the righting sucker rod reduces the friction between the rod and the tube and enhances the oil recovery life of the pumping unit.

Structure:

The sliding sleeve sucker rod centralizer consists of a core rod, a sliding sleeve and a joint.

Features:

1. Spray a thick metal lubrication film on the surface of the centralizer by spray welding.

2. The material of the metal lubricating film is nickel-based alloy powder with a nickel content of 60% and other components such as chromium, boron, silicon, and the like.

3. With three wear-reducing surfaces, the line contact of the traditional centralizer is changed to face contact. The contact is more complete and the anti-bias effect is more obvious.

previous page

next page

previous page

next page